Senin Technology

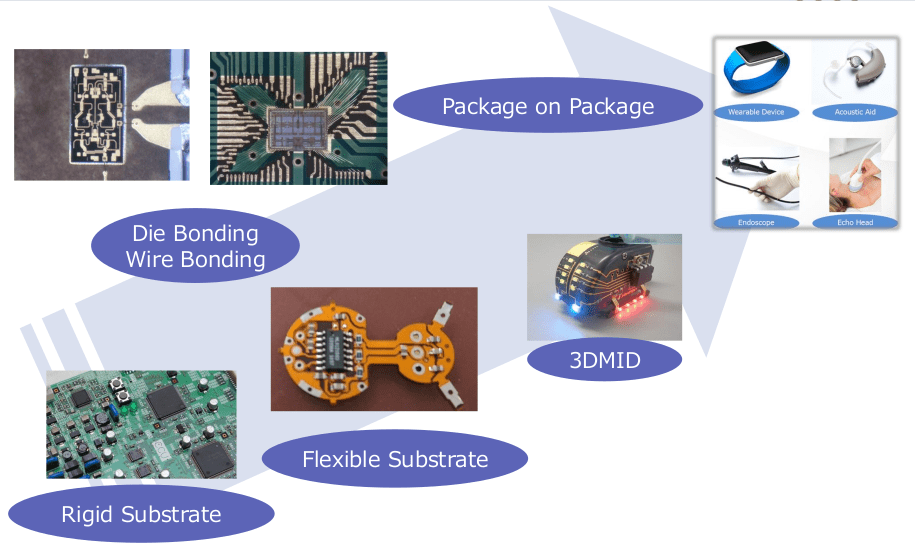

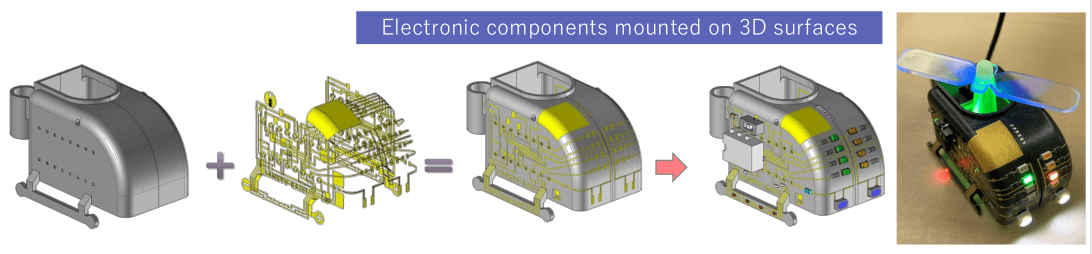

3D Molded Interconnect Device (MID) technology is the lastest innovative technology that replaces Rigid circuit boards by utilizing a 3-dimensional circuit on molded plastic . This allow a more compact integration of electronics components to fit into the available space for small applications

As many devices continue to get smaller and more compact , there are many challenges to fit into the application with wires and components using conventional circuit boards . As such, many markets will benefits from 3D MID technology from Senin.

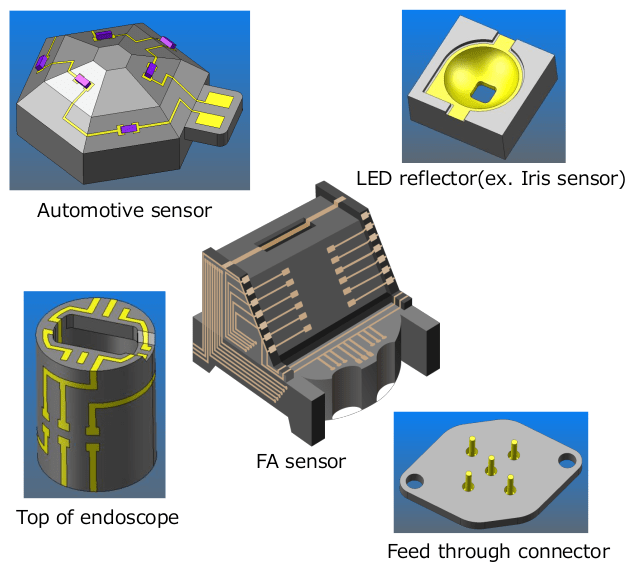

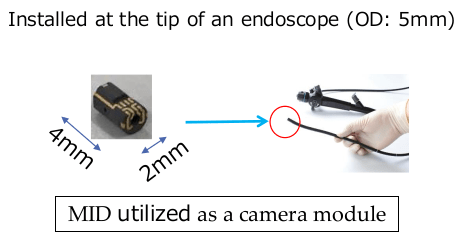

Senin 3D-MID technologies are able to make the current product smaller and lighter, which is ideal solution not limited to hearing aids, implants and surgical (endoscope) and dental instruments. The technology has no limit in usage including advance developments in the areas of wearables, Transducer , antenna applications ; automotive steering wheels, ADAS etc.

MID Technology can realize the Highly Integrated Device

- Injection molded component on which circuit traces are directly applied

- Both electronic and mechanical functions integrated

Molded Interconnect Device

Benefits of our 3D MID

Benefits of our 3D MID

- Miniaturization/ Weight Reduction

- Higher design flexibility

- Greater functional density

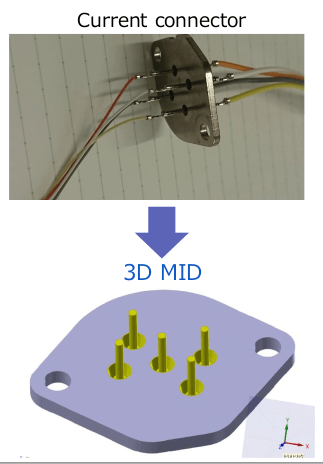

3D MID for feedthrough connector

3D MID for feedthrough connector

- Suitable for Gas/Smart meter

- Cost effective material instead of glass

- SMT available on the top of connector

Structure : 3D MID

Material :

| Pin | Brass | Ni Au Plating |

|---|---|---|

| Base Material | LCP PPS | Ceramics |

| Junction | Solder | AuSn |

Airtightness : 1×10-9↓ Pa m3/s

Reliability Test (min.hours and cycle)

- Heat shock -40⇔+80 by30 minutes 1000cycle

- High humidity :60°C×240hrs. 70°C×3500hrs.

- High temp.hum. :70°C、 95%RH 240hrs.

- Low humidity :-30°C×240hrs.

Future Feasibility