Description

Key capabilities

Turnkey circuit layout and packaging design based on customers’ electrical schematics, and performance and environmental requirements.

Design and manufacture in compliance with MIL-PRF-38534 Class H.

Engineering and program management support.

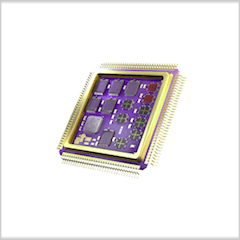

A broad range of packaging and technologies, including:

- Hermetic and non-hermetic packaging

- Multi-layer thick film printing on ceramic (AIO and AIN)

- High and low temperature co-fi red ceramic (HTCC and LTCC)

- Thin film

- Surface mount

- Bare die and wire bonding (or mixed SMT and With Chip & Wire)

State of the art ‘lean’ manufacturing facilities, including:

- Class 10,000 clean room facilities in the US and UK

- Fully automated SMT lines

- Fully automated die bonding and wire bonding

- Automated inspection (under development for wire bonding)

- Custom test systems including full temperature testing

- Environmental screening to MIL-STD-883, ESA ECSS-Q-ST-60-05 and BS9450

ISO9001:2008 and IS014001:2004 quality management systems Applications

Applications

Our diverse range of custom solutions have recently been adopted in the following applications:

- Aircraft engine control• Airborne phased array radars

- Aerospace / space inertial measurement units

- Wing ice protection systems

- Electronic counter measures

- Missile fusing / seeker systems

- Helicopter mission computer systems

- Minesweeper sonar systems and beacons

- Suppressor circuits for aircraft lightning protection

- High voltage mass spectrometer circuits

- Optical test instrumentation

- Oil and gas exploration pressure and temperature logging modules